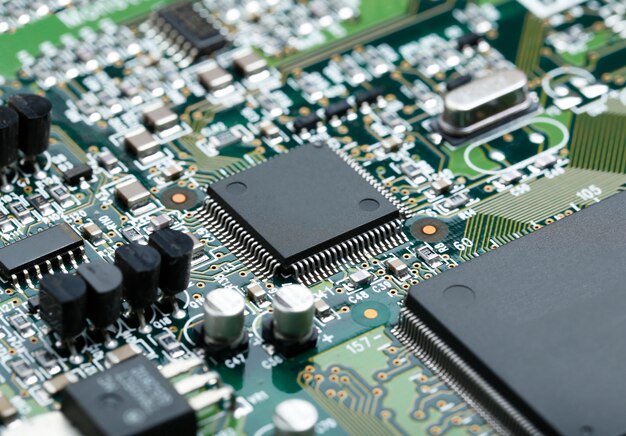

Silicone components are widely demanded for manufacturing different types of electronic products. This material is so significant that it can be easily identified as the “backbone”of many electronics businesses.

Due to this significance, it becomes necessary for these businesses to acquire high quality Silicone components from top-ranking Silicone prototype manufacturers.

These professional manufacturers develop high quality Silicone components, through the procedure of injection molding of liquid Silicone rubber. In this post, we will get to know more about this process for better clarity.

Step-By-Step Process Of Liquid Silicone Rubber Injection Molding

Top-reputed Silicone prototype manufacturers, follow every steps of liquid Silicone rubber injection molding such as:

- Creating The Liquid Silicone Rubber Moulding Tool

Usually, the injection molding tool is designed with the help of specific CNC machines. During this, the moulding tool is developed to possess high temperature resistance, which is necessary for the effectiveness of the injection molding.

Additionally, the tool can also be polished to meet different finishings, whenever needed. The final molding tool is then inserted in the liquid Silicone rubber moulding press.

- Preparing The Liquid Silicone Rubber Material

The uncured liquid Silicone material is prepared in two different containers that are connected to the pumping systems. In one container, the base forming material is kept. Whereas the other container is used for keeping the Platinum-based catalyst.

Both the base material and the catalyst are pumped inside a static mixer, with the help of a specific metering pump. Also, an additional colour pigment is added along with the required additives, before putting both the materials into the static mixer. The ratio of both the materials is one to one.

- Injecting The Liquid Silicone Rubber Into The Mould

Professional Silicone prototype manufacturers now heat up the liquid Silicone rubber material. After this, they inject it into the mould cavity, with a nozzle and under high pressure. Once all the mould cavities are filled, the Silicone rubber material gets the shape of the mould. This also decides the shape of the final liquid Silicone rubber products.

Here, high pressure is necessary to ensure that the material is filled in all areas of the mould cavity. This helps to develop all the details and features on the Silicone material.

- The Curing Procedure

After injecting the material into the mould cavity, it then heated up to commence the curing procedure. In this procedure, the liquid Silicone rubber is converted into solid Silicone rubber components.

The specific size and complexity of the components, determines the actual time required for the curing process.

- Cooling And Demolding

This is the most important step in the process of injection molding of liquid Silicone rubber. After the liquid Silicone rubber is properly cooled down, they will be removed from the mould cavity and separated. This thing is done with the help of specific automated systems.

However, if the production volume is very less, then manual workers are responsible for dealing with this task. Due to the inherent properties of the liquid Silicone rubber material, flashings in the moulding process are not very frequent.

- After-Moulding Secondary Operations

Performing secondary operations after the moulding process can be necessary. It includes a range of jobs such as printing, marking and assembling along with slitting and post-curing.

The Benefits Of Injection Molding Of Liquid Silicone Rubber

There are many benefits of injection molding of liquid Silicone rubber such as:

- Durbality

Injection molded Silicone parts have high UV resistance and ozone proofing, with huge electrical insulation. These types of Silicone parts are widely used for making different electronic gadgets and its related applications.

- High Precision And Accuracy

The Silicone parts developed with the process of injection moulding, have high precision and accuracy. The final product is always according to the desired results. It will be of the right size and shape, along with every detail.

- Automated Processing

Injection molding of liquid Silicone rubber is totally an automated procedure. The parts will not have any connection with the outside environment, unless the production volume is very less. But here also, professional Silicone prototype manufacturers can use machines to reduce human errors.

- Low Waste Generation

The injection molding is considered as an eco-friendly procedure. This is because it usually generates zero to very low waste, throughout the process. Also, the Silicone material can be easily recycled to make other electronic items. This ultimately reduces the carbon footprint of the electronic businesses, and helps them to move towards green productions.

Conclusion

We got to know the step-by-step procedure of injection molding of liquid Silicone rubber, followed by top-ranking Silicone prototype manufacturers. Along with this, we also understood the ultimate benefits of injection molding for liquid Silicone rubber materials, in this post.

This will help the electronic businesses to have every detail about this procedure. With this, they can have the best Silicone components supplied for their product design and development.