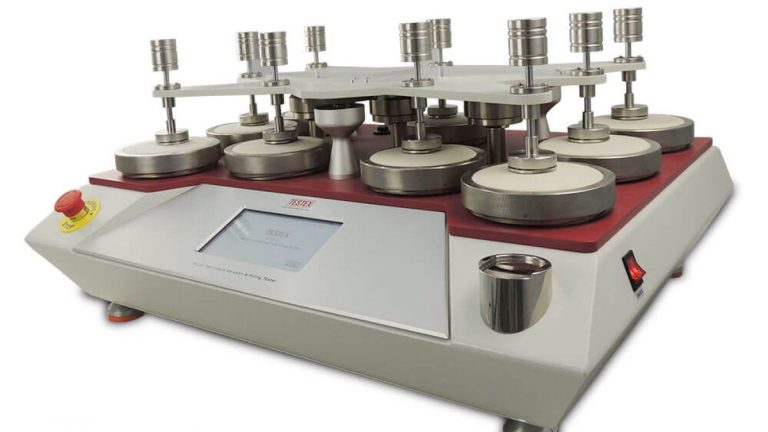

The Martindale Abrasion and Pilling Tester is a vital instrument in the textile industry, designed to assess the durability and appearance of fabrics under conditions of wear and pilling. By simulating the mechanical stresses that textiles endure during use, this tester provides manufacturers and quality control laboratories with essential data to ensure product quality and longevity.

Understanding the Martindale Tester

Developed in the 1940s by Dr. Martindale, the Martindale Abrasion and Pilling Tester evaluates two primary aspects of fabric performance:

- Abrasion Resistance: This test measures the fabric’s ability to withstand surface wear caused by rubbing against another material. The specimen is subjected to repeated rubbing motions, typically in a Lissajous pattern, to simulate real-world usage. The number of rubs until the fabric shows signs of wear or damage is recorded, providing a quantifiable measure of abrasion resistance.

- Pilling Resistance: Pilling refers to the formation of small balls of entangled fibers on the fabric’s surface, which can detract from its aesthetic appeal. In this test, the fabric is rubbed against an abrasive material under controlled conditions to induce pilling. The extent of pilling is then assessed, often using standardized photographic references, to determine the fabric’s performance.

Key Features and Specifications

Modern Martindale testers are equipped with advanced features to enhance testing efficiency and accuracy:

- Multiple Test Stations: Available in configurations ranging from 4 to 9 stations, these testers allow simultaneous testing of multiple samples, streamlining the evaluation process.

- User-Friendly Interface: Equipped with intuitive touchscreen controls, operators can easily set up and monitor tests. Features like individual station counters and timers facilitate precise tracking of test progress.

- Adaptability: The tester can accommodate various fabric types and testing standards, including international and proprietary protocols such as ISO 12947-1, ASTM D4966, and M&S P17.

- Safety Features: Designed with safety in mind, these testers include features like emergency stop buttons and safety shields to protect operators during testing.

Applications in the Textile Industry

The Martindale Abrasion and Pilling Tester is indispensable across various sectors:

- Apparel Manufacturing: Ensures that garments, especially those subjected to frequent wear, maintain their appearance and functionality over time.

- Upholstery and Furnishings: Assesses the durability of fabrics used in furniture and home textiles, where both abrasion and pilling resistance are critical for consumer satisfaction.

- Automotive Textiles: Evaluates materials used in vehicle interiors, which must withstand constant friction and maintain aesthetic appeal.

Conclusion

In summary, the Martindale Abrasion and Pilling Tester is a cornerstone in textile testing, providing manufacturers with the tools to produce high-quality, durable fabrics. By accurately simulating real-world conditions, it ensures that textiles meet the rigorous demands of consumers and industries alike.The Martindale Abrasion and Pilling Tester is a specialized testing apparatus designed to simulate the wear and tear a fabric undergoes during normal use. Developed in the early 1940s by a British textile engineer named Martindale, the tester is widely used for assessing fabric durability, including its ability to resist abrasion and the formation of pills (small clusters of fiber balls on the surface of the fabric).

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: [email protected] [email protected]